Complex Leak Enclosures Possible with 3D Metrology

The Client’s Critical Issue

An oil drilling operation struggled with a nagging pipe leak problem. Sand coming up from the ground along with the crude oil was wearing away at their rig’s piping system – especially where the pipes made 90-degree bends. The company had to routinely shut down the rig to repair the pipes. It was a long, drawn-out maintenance process that could sometimes take up to a month to complete.

The traditional repair process – tearing down the damaged pipes, taking measurements manually, and designing, building, and installing custom replacement pipes – was a laborious, time-consuming task. Plus, there was no slam-dunk guarantee the replacement pipes would precisely refit to the full piping system’s configuration.

The Dimensional Engineering Solution

The oil company’s field-engineering firm proposed a very different way to tackle the pipe leak problem – a method both more efficient and more effective. They contracted with Dimensional Engineering to help make it happen.

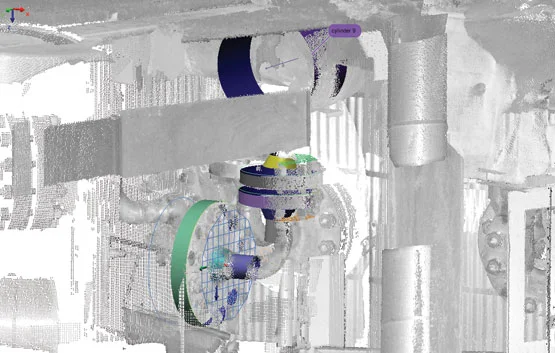

First, we used the latest laser scanning and tracking equipment – battery-powered and non-contact – to collect pipe measurements. We measured digitally, not by hand, for higher accuracy. Shooting directly into the pipes’ headers, we determined the dimensions on four full pipe trains – all in just two hours. No pipes had to be removed from the system while these data were captured.

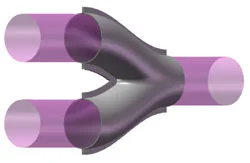

With digital measurements taken, we next turned to CAD software to design custom enclosures for the worn areas of the pipes. The approved designs were quickly fabricated. Four enclosures were fitted to the pipes. All have worked perfectly; they fully encapsulate the pipes’ sensitive areas and minimize further risk of leaks.

The Value We Provided

Bottom-line benefit: The oil rig suffered total downtime of just hours, rather than weeks – thanks to this innovative new-school approach.

Want to know about new and improved methods of pipe leak repair. Download our “Breakthroughs”article (PDF, 890 Kb) to get the full story.