Dimensional Control

A common desire in all industries is the reduction or elimination of reworks during the manufacturing and fabrication process. The dimensions of production tools, parts, and products need to be documented in order to mitigate the costly risks associated with reworks. The digital documentation and control of production tools is critical in ensuring consistent manufacturing in the shop and machining in the field. The same principle of having complete traceability by digitally documenting finished products allows the root cause of non-conforming pieces to be determined in a fraction of the time compared to using traditional tools.

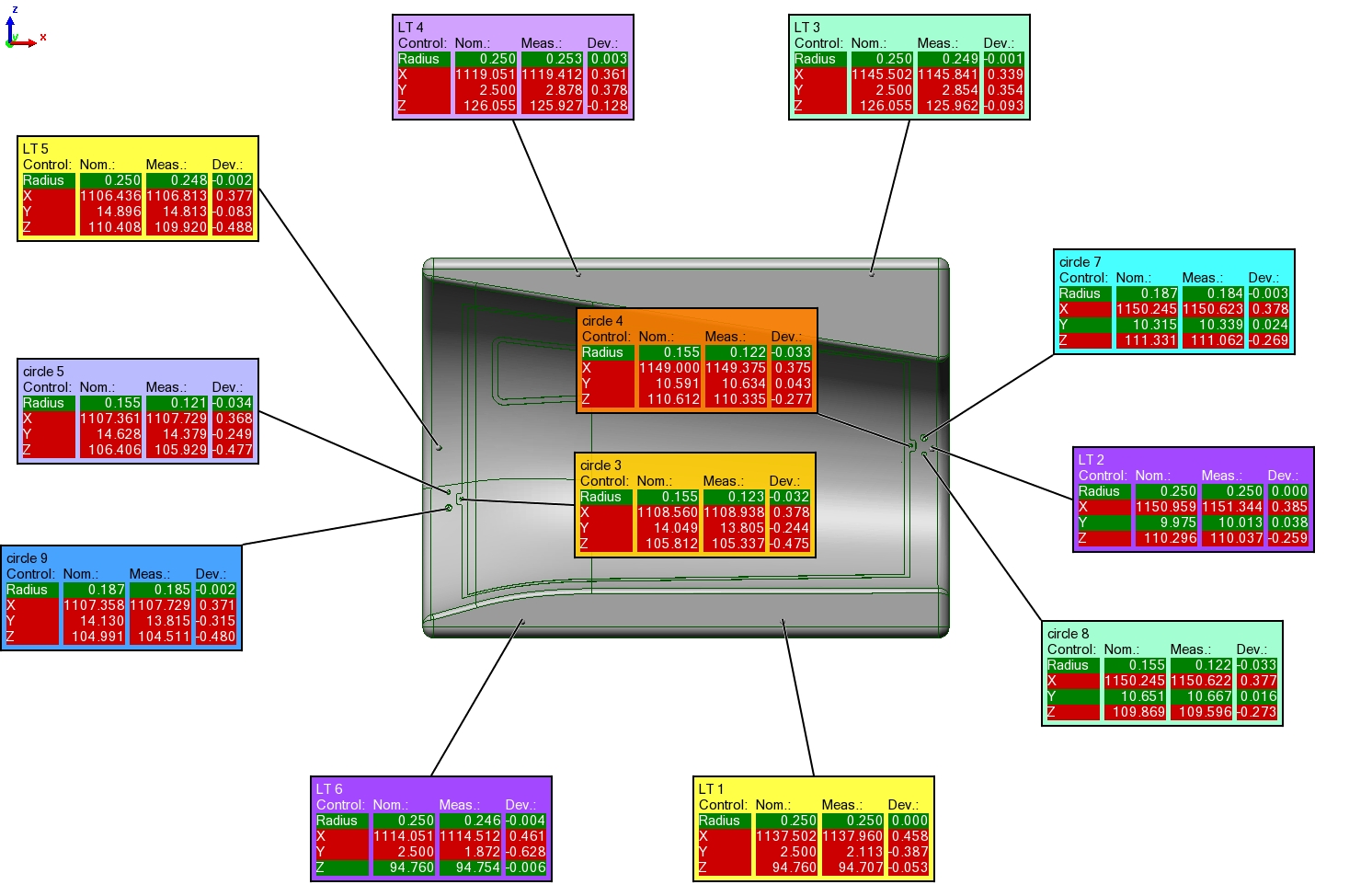

Dimensional Engineering’s Dimensional Control services enable an entire process to be documented from the as-found to the as-left condition of equipment, parts, and tools. This allows the high-precision and high-accuracy guiding of critical field machining, pipe-fitting, flange refacing, and equipment alignment from start to finish. All of these processes can be performed in a shorter amount of time because of the accuracy and precision of our equipment, which results in a significant reduction of costly contractor rentals. With our Dimensional Control services, the goal is to objectively determine the state of your equipment and assist in the setup of any field machining, so you can be sure it’s done right the first time.