Reverse Engineering (Scan to CAD)

Capture and analyze 3D digital data from physical machines, tools, and parts

Dimensional Engineering can help you bridge the gap between the physical and virtual worlds. We pioneered the use of non-contact laser scanning and laser tracking technologies for reverse engineering, and we continue to lead the field. We apply the latest hardware and software, along with our unmatched experience and expertise, to capture physical objects of all kinds in 3D digital data.

Any Product or Part, Any Size or Complexity

Using the latest non-contact laser scanning and tracking equipment, we can produce highly accurate digitized surface mapping of practically any product or part, regardless of its complexity. Our reverse engineering services are scalable from an object as small as the cell phone in your pocket to a structure as large as a full-size aircraft.

You Get the Tools and the Talent

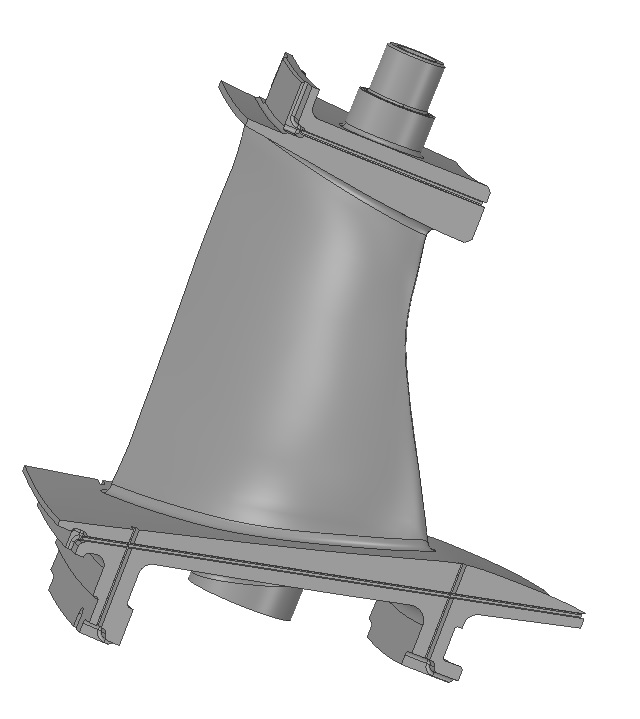

Having the best tools for reverse engineering is only part of the Dimensional Engineering advantage. Our value to you comes from knowing precisely how to implement the technology to achieve optimum results. Our team brings more than just hardware and software to your site; we bring our in-depth know-how gained from decades of background in a variety of industries and product specialties. We have reverse-engineered everything from turbine engine components to complete vehicles.

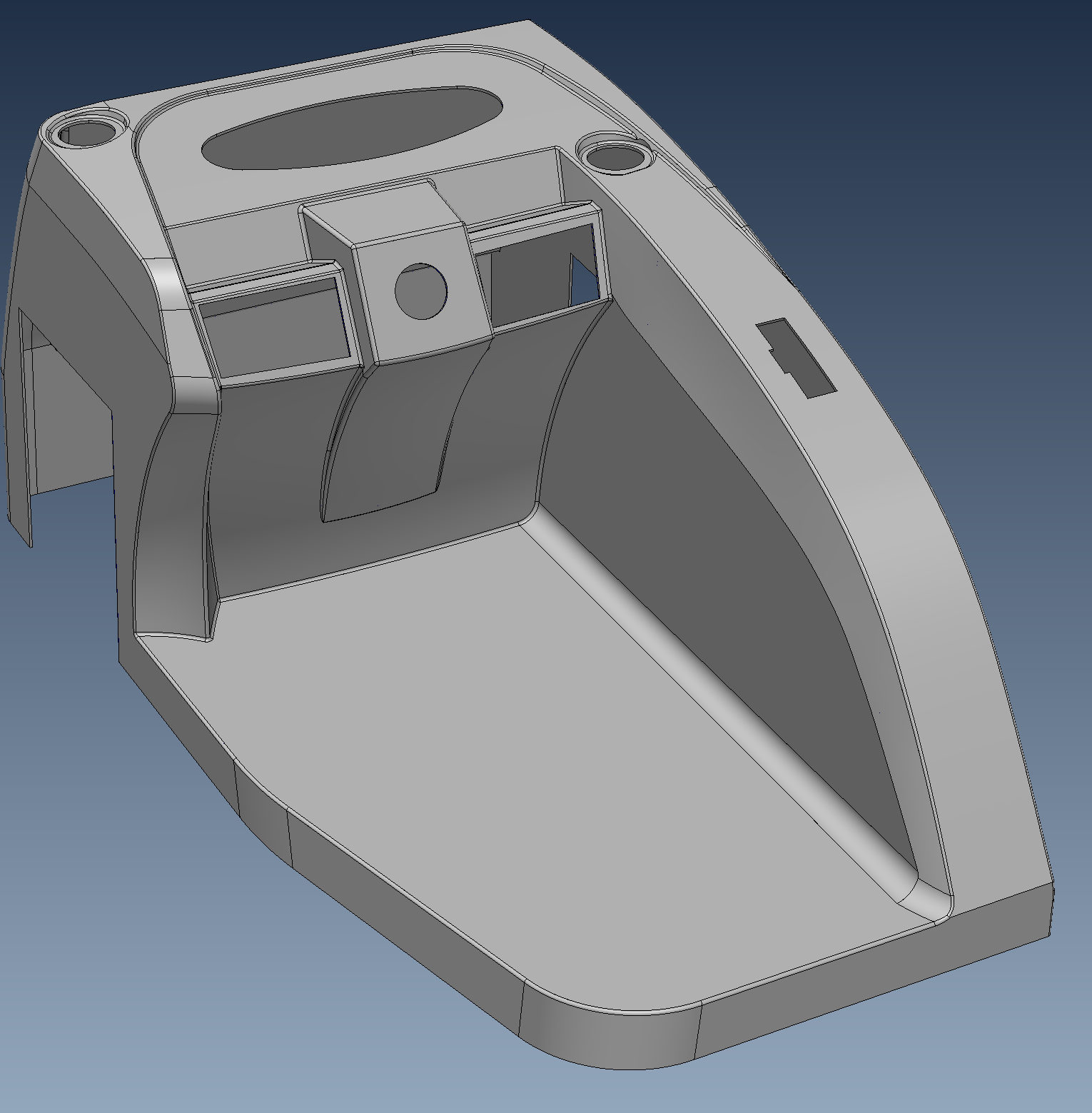

CAD Models of the Highest Precision

Our methods of 3D Scanning and post-processing of data produce high-quality CAD models that you can use for further engineering development. Our process ensures utmost precision with fast turnaround.

Data Acquisition Technology

Non-Contact Laser Scanner

Photogrammetry

Laser Tracker

Coordinate Measuring Machine (CMM)

Reverse Engineering Deliverables

CAD Models

Solid Models

STL Models

Other Client-Specified Models

Virtual Assembly

Digital Mock-Up

Full Assemblies and Sub-Assemblies

Build Analyses

Reverse Engineering Case Studies

Learn how we have helped clients meet critical design and production challenges using our reverse engineering tools and processes: