Virtual Build & Bolt

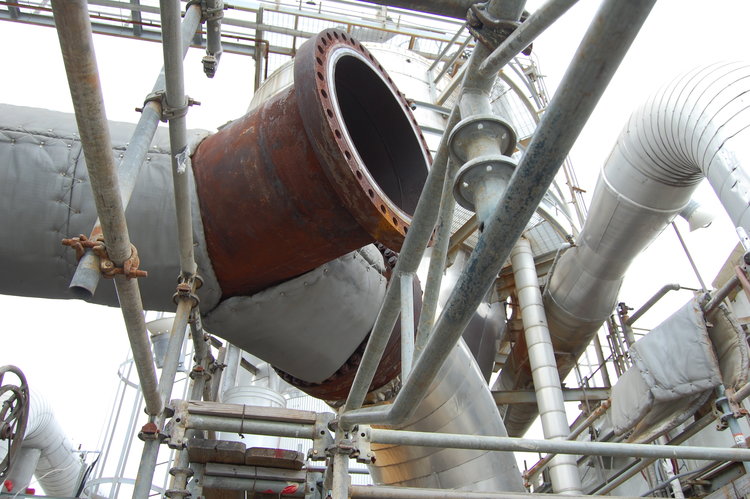

In the current economic climate, ensuring projects are on-time and on-budget are of the utmost importance. This is especially important for modular builds, as fabrication errors found during installation that need to be corrected have a significant cost of both time and money. Dimensional Engineering has a Virtual Build & Bolt process that can help you mitigate these costly risks. With our process we can help you certify the design of your modules built in different locations, even if they are on opposite sides of the world. Our certification process ensures that the final assembly can be delivered and assembled with confidence that all modules will fit into place without modification.

Our Virtual Build & Bolt process works by combining non-contact laser scanning and laser tracking technologies to capture an entire plant facility or modular build for offsite review. During the review we align the data of multiple modules and check for any gaps, overlap, and angular issues between connecting portions. We then take those results and put them in a report that is clear and easy to understand so that our clients can make the necessary modifications.

Our process has been proven to help our clients:

Save time and cut costs by discovering and correcting errors upfront

Increase traceability by having an electronic, 3D documentation of the entire project

Increase safety by being able to collect all data on the ground, eliminating the need for scaffolding or harnesses