Bottom-line benefit: The oil rig suffered total downtime of just hours, rather than weeks – thanks to this innovative new-school approach.

Read MoreThe client now has the security they were previously lacking. They know that if recreating the specialized fiberglass tooling should ever be needed, they have accurate, up-to-date 3D digital data that can spare them from unnecessary retooling expense.

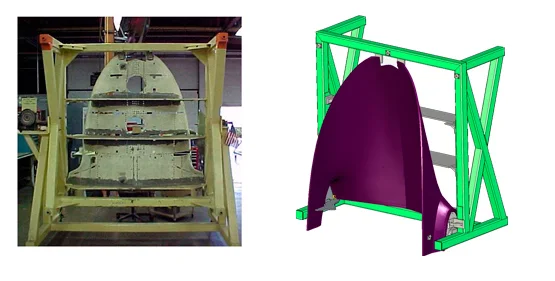

Read MoreIn the past, the client needed to rebuild lost or damaged models, using the fragile 2D engineering drawings, and recertify them with the Federal Aviation Administration (FAA). Now, the digital data is on file, allowing fast and smooth recreations.

Read MorePer the client, “Dimensional Engineering responds immediately when we need them. Their expertise in 3D digital data capture has been a tremendous asset to us. The technology they apply is as accurate as it gets.”

Read MoreThe finished model documented every detail of the drill fixture in a complete bill of materials (BOM) list. The manufacturer’s quality assurance department certified the data to ensure that the required accuracy criteria were fully met. Once QA approved the data, it was used to duplicate the series of tools.

Read MoreThe solid model captured by Dimensional Engineering enabled the manufacturer to run crash simulations and understand how effectively the trailer’s new safety features would work in real-life crash situations.

Read MoreA total of four AICM dispensers were retrofitted to the aircraft’s outer skin, with a complete mounting structure inside the aircraft. The project was completed before the deadline, and the quality exceeded the client’s highest expectations.

Read More